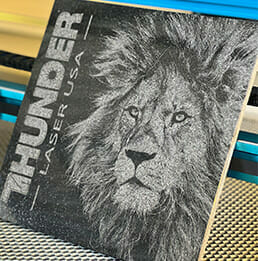

It’s not an uncommon question when investing in a unit from a company like Thunder Laser USA: How loud are Thunder Lasers’ machines? If you’re running a Thunder Laser machine, especially if you’re in a shared domestic space or for educational, commercial or public use, it can be important to understand how much sound it could produce while in operation. There’s a common perception that laser cutters are noisy, and we’ll be addressing that idea here.

Laser Sound: Expectations and Reality

Laser machines can be a tremendous asset or even a cornerstone of a business enterprise or public organization’s endeavors, or for that matter a creative person’s self-expression. But in any environment, you’ll want to be sure they’ll mesh with the kinds of conversations and other activities that will be part of everyday work and life.

The most common level of sound produced by laser machines is around 75 decibels when in full operation and 10 to 20 fewer decibels than this when idling. To put this in perspective, a normal conversation happens in a range around 60 decibels.

What exactly this might mean for you will depend on the particulars of where you’re running your engraver. In most warehouse or office environments, noise levels around 75 decibels should not be a significant disruption.

If, on the other hand, you’re running a Thunder Laser machine in a residential workshop, or near any place where speeches or presentations might be happening, other people in the vicinity might object to the noise at certain times of day. This is something you’ll need to work out depending on the tolerance of other people sharing the space.

The Thunder Laser Nova 35-80: An Unofficial Test

We can see more specific data in an unofficial test of the sound levels that an 80-watt Thunder Nova 35 created in various phases of operation or idling. This test was carried out with a Radio Shack Digital Sound Level Meter while the machine was idling, powering up and running a job, respectively.

NOTE: This test and the accompanying results are UNOFFICIAL and do not follow best practices and procedures for sound pressure level measurement so its for educational purposes only. Thunder Laser USA always recommends the use of appropriate ear and eye protection at all times. I cannot guarantee the accuracy of these tests or the results.

In each of these modes, the sound levels were as follows:

- The ambient noise produced when all equipment was off registered as 34 decibels.

- While the alarm was activating on the chiller, the sound level was approximately 68 decibels.

- At its loudest, the machine’s power-up sequence reached around 48 decibels.

- With its air assist pump running, the machine at idle produced around 50 decibels.

- With the air assist pump and chiller in operation, the machine idled at about 60 decibels.

- The full operation of all systems put out around 74 decibels of sound.

What this amounts to is that in the environment where it was tested, the Thunder Laser Nova 35 was about as loud as running a vacuum cleaner.

A Note About Testing

Measuring your Thunder Laser sound output would normally, for maximum accuracy, follow best practices and standard procedures for sound pressure level measurement. The reason the above test is flagged as unofficial is that it was more informal than this and is thus for educational purposes only. The accuracy of an informal test can’t be guaranteed.

The measurements on the unofficial test were A-weighted, which means the levels were filtered to mimic an average human ear’s frequency range (you can read more about weighting here). If you’re unsure of your specific setup’s sound output levels or want the most accurate possible readings you can get, it’s worthwhile to contact an industrial audiologist to get a professional evaluation.

Thunder Laser USA always recommends the use of appropriate ear and eye protection gear whenever you’re operating your equipment.

Further Considerations for Laser Cutter Noise

Although laser cutters often don’t produce high levels of sounds, it’s nevertheless true that they do produce a moderate level of noise when in operation, and jobs can run for long periods of time depending on various considerations like the specifics of the material and the level of detail, especially for engraving jobs. They also require exhaust and cooling solutions.

For these reasons, where you put your laser cutter will matter:

- It should be in a place where noise level roughly equal to that of a vacuum cleaner, and smell from the material, will not be a problem. In some environments, even slight levels of noise and smell could prove to be a disruption.

- It should be in a place where there’s both sufficient air intake and a means to install an exhaust tube that’s as short and straight as possible. Having both air intake and an outlet for the exhaust are equally important: Wherever there isn’t enough air intake, negative pressure in the room can suck in unwelcome smells through sources like drains.

- It should be somewhere that has room for a cooling system. Most laser cutters are water-cooled, which means the need for a cooling system that constantly circulates distilled water through the laser tube.

For a fuller explanation about the kinds of exhaust, filtration and cooling solutions you might need, you should talk with an expert at Thunder Laser USA.

Contact Thunder Laser USA Today

To begin enjoying the benefits of Thunder Laser machines’ power and flexibility for commercial and industrial laser cutting, printing and engraving, get in touch with Thunder Laser USA and talk with an expert member of our team. They’ll be happy to put together the best possible solution for you and to provide you with peace of mind about common anxieties about the smell and sound effects of a laser cutter.