Looking for laser engraving tips and tricks that can take your laser engraving projects to the next level? Laser engraving is a versatile and precise method for creating professional-quality designs on a variety of materials. With the right tips and tricks, you can maximize the potential of your laser engraver and create stunning, intricate designs that leave a lasting impression.

In this blog, we’ll explore seven expert tips and tricks for getting the most out of your laser engraver. From choosing the right materials to mastering engraving techniques, we’ve got you covered with all the laser engraving tips and tricks you need to know. So let’s dive in and discover how to take your laser engraving projects to new heights!

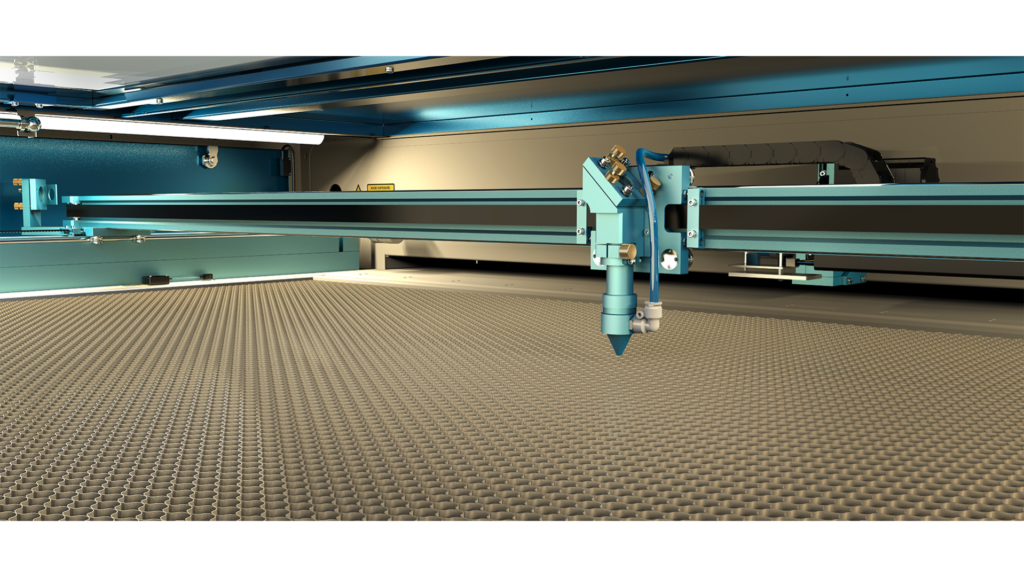

Use High-Quality Materials

When it comes to laser engraving, using high-quality materials is top of the list for essential tips and tricks. Great materials are absolutely crucial to achieving the best results. Certain materials work better with laser engravers than others, and choosing the right material can make a significant difference in the quality of your project.

For example, wood is one of the most popular materials for laser engraving because of its natural beauty and versatility. Hardwoods like maple, cherry, and walnut offer a more consistent and precise engraving result, while softwoods like pine or cedar may be less precise due to their softer nature. Acrylic is another popular material for laser engraving due to its durability, affordability, and the ability to create intricate designs with clean edges. Cast acrylic is preferable to extruded acrylic because it provides a cleaner, more polished finish. Glass and metal can also be laser engraved, but require specific considerations and techniques.

Using high-quality materials can improve the overall outcome of your project in several ways. High-quality materials are typically more durable, which can increase the longevity of the engraved design. They also tend to have better surface finishes, which can enhance the clarity and detail of the engraving. In addition, high-quality materials are often easier to work with, reducing the risk of errors or issues during the engraving process.

In short, investing in high-quality materials for your laser engraving projects can pay off in the long run by improving the overall quality and longevity of your work.

Proper Maintenance and Cleaning

Proper maintenance and cleaning are essential for getting the most out of your laser engraver. Neglecting to take care of your machine can lead to poor performance, breakdowns, and a shorter lifespan. Here are some tips to help you keep your laser engraver in top condition:

- Regularly clean the lens: The lens of your laser engraver can accumulate dirt and debris, which can affect the quality of your engravings. Use a soft, lint-free cloth to clean the lens and ensure that it is free from smudges, dirt, and other contaminants.

- Clean the machine after each use: After each use, wipe down the machine with a soft, damp cloth to remove any dust, debris, or other particles that may have accumulated on the surface. This will help prevent build-up and ensure that your machine runs smoothly.

- Check the mirrors: The mirrors in your laser engraver are essential for directing the laser beam to the right spot. Check the mirrors regularly to make sure they are clean and free from scratches, cracks, or other damage.

- Keep the machine lubricated: The moving parts of your laser engraver require proper lubrication to function correctly. Check your machine’s manual to determine the appropriate lubricant to use and how often to apply it.

Proper maintenance and cleaning will not only ensure the longevity of your laser engraver but also improve its performance. A clean machine produces better quality engravings and reduces the risk of breakdowns, which can save you time and money in the long run.

Experiment with Power and Speed Settings

Experimenting with power and speed settings is an essential part of the laser engraving process. It involves adjusting the laser’s power and speed to achieve the desired outcome for your project. Understanding how to experiment with these settings can help you achieve optimal results and save time in the long run.

When experimenting with power and speed settings, it’s important to start with low settings and gradually increase them until you find the right combination for your project. Keep in mind that the settings will vary depending on the material you are working with, so it’s important to test each material before starting your project.

To test the settings, create a small sample on a scrap piece of the same material you’ll be engraving on. Begin with the lowest power and speed settings and gradually increase them until you achieve the desired effect. Keep notes on the settings you use for each material so you can refer back to them for future projects.

Finding the right power and speed settings can save time and increase efficiency. Using the correct settings can reduce the number of passes needed to achieve the desired outcome, which can speed up the process and reduce wear and tear on your laser engraver. Additionally, using the correct settings can help minimize material waste and increase the quality of your final product.

Use Appropriate Software

When it comes to laser engraving, the software you use can make a significant difference in the outcome of your project. It’s essential to choose software that is compatible with your laser engraving machine and provides the features you need to achieve the desired results.

Some software programs that work well with laser engravers include LightBurn, Adobe Illustrator, CorelDRAW, and AutoCAD. These programs offer a range of tools and features that allow you to create precise designs and control the settings of your laser engraver.

Using appropriate software can also save you time and increase your efficiency. With the right software, you can import designs, make adjustments, and send the file directly to your laser engraver, streamlining the entire process. Additionally, some software programs provide pre-set material settings that can help you achieve optimal results for specific materials, such as wood or acrylic.

When selecting software for your laser engraving projects, it’s essential to consider your specific needs and budget. Some software programs can be expensive, while others are free or low-cost. Look for a program that offers the features you need without breaking the bank.

In conclusion, using appropriate software is crucial for achieving high-quality results in your laser engraving projects. Take the time to research and select the best software for your needs and budget, and you’ll be on your way to creating stunning and precise laser engravings.

Make Use of Templates and Stencils

Also, when it comes to laser engraving tips and tricks, one way to save time and create consistent designs is by using templates and stencils. Templates and stencils are pre-made designs that can be downloaded or created to fit your specific project needs.

By using templates and stencils, you can ensure that your designs are consistent and precise, without having to spend hours creating them from scratch. For example, if you are engraving a company logo onto a set of awards, using a pre-made template can save time and ensure that each award is engraved with the same design.

There are many resources available for finding templates and stencils, such as online marketplaces like Etsy or design software like Adobe Illustrator. You can also create your own templates and stencils by using design software or by tracing existing designs onto a material like paper or plastic.

In addition to saving time, using templates and stencils can also help with design accuracy. With a pre-made template or stencil, you can ensure that your design is the correct size and proportions. This is especially useful when creating complex designs that require multiple layers or intricate details.

Overall, incorporating templates and stencils into your laser engraving process can help you save time, increase efficiency, and create consistent, precise designs. So, take advantage of these resources to elevate your laser engraving projects to the next level.

Consider the Material Thickness

When it comes to laser engraving projects and tips and tricks, material thickness plays an important role in achieving the desired outcome. It’s important to consider the thickness of the material you’re working with, as it can impact the depth and clarity of your engravings.

To accommodate for different material thicknesses, it’s important to adjust the laser engraver accordingly. Some laser engravers have a height adjustment feature that allows you to adjust the distance between the laser and the material. This can help you achieve the desired depth of your engraving without damaging the material.

Another important factor to consider when working with different material thicknesses is the power and speed settings of your laser engraver. A thicker material may require higher power settings and slower engraving speeds to achieve a deeper and clearer engraving.

By taking the time to adjust your laser engraver to accommodate for different material thicknesses, you can achieve a more professional and polished look for your project. So always consider the thickness of the material you’re working with and adjust your laser engraver accordingly to ensure the best possible outcome.