When you get a laser cutting machine, one of the most exciting initial considerations is thinking about what you’re going to make. The best thing to do is start off very simple, with a basic engraving business model or a small line of products. However, as your skills improve, it’s likely you’ll want to branch out and add new strings to your bow.

At Thunder Laser USA, we sell a range of CO2 laser accessories to help take your laser cut game to the next level.

Enhance Your Laser Engraving and Cutting With Laser Cutter Accessories

COVID-19 has changed the world and left many people feeling uncertain about their future careers. If you’re ready to wave goodbye to the daily grind and be your own boss, a laser cutting machine could be just the solution.

Whether you use your CO2 laser tube to engrave, cut or etch, one thing’s for certain: You can do just as much with a laser cutter as you can with a 3D printer for a lot less money. Whether it’s your dream to create gifts and souvenirs, engrave trophies or make bespoke jewelry, you can do it with a Thunder Laser USA cutting machine.

There are so many options for things to do with this piece of equipment that it can seem overwhelming at first. However, it’s important to note that you don’t need any previous experience with a similar machine. You don’t even need to know how to draw. You simply upload 2D image files into the machine and it does all the magic for you.

You may need some time initially to get used to creating the 2D drawings and using the machine, but after a small learning curve, you’ll be a master. Some of the things you can do with your laser cutter include:

- Engraving branded glassware and linens

- Making trinkets

- Shoemaking

- Engraving school and sports trophies

- Creating bottle openers and key chains

- Making coasters and beer mats

- Acrylic jewelry

- Making laser wax seals from acrylic

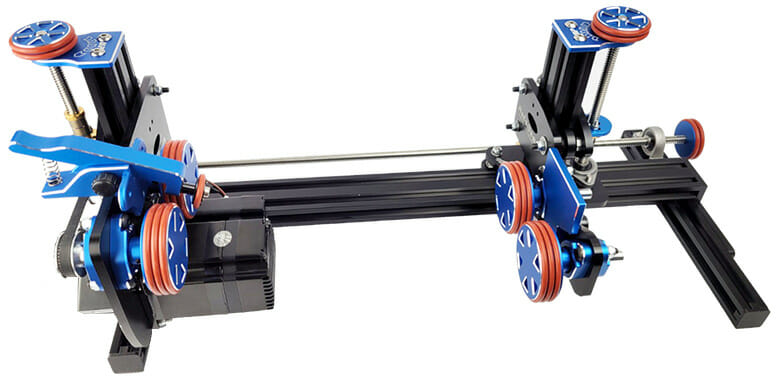

Rotary Devices for Laser Engraver Machines

Rotary devices are essential pieces of equipment for many items of manufacturing machinery that necessitate marking cylindrical objects. They manipulate and turn your round or conical material to guide the laser beam to its target. If you want to engrave these types of objects, you’ll need to get a rotary device as laser machines don’t come with them fitted as standard.

Why Choose RotoBoss Rotary Attachments?

RotoBoss products have been cited by many people as being the best rotary attachments available. They provide the functionality of industrial-grade rotaries but at a fraction of the cost. For a small investment in a rotary device, you could start a business that makes thousands of dollars a month.

The RotoBoss and RotoBoss Jr. are both designed to fit in the Nova35, the Nova51 and the Nova63, while the Low Roller goes with the Nova24 and Odin models.

RotoBoss

All RotoBoss models have rubber feet that let your rotary effortlessly attach to any surface, including inside your machine. The feature that sets the RotoBoss apart from the Roto Jr. is that it has two adjustments on the slave wheel and motor drive side. You can adjust both sides to suit the product you’re making and it won’t interfere with your system.

It’s operated using a belt drive and cam tensioner that you might need to adjust as the belt breaks in. There’s even a removable heel plate you can take off to make longer items and a mug spacer specifically designed to protect the handles when you’re making mug designs.

Roto Jr.

The Roto Jr. is a slightly simplified version, with just one vertical tower that raises and lowers on the slave wheel side and a single thumbscrew for locking heavy objects into place. Otherwise, it’s the same — it uses an adjustable cam tensioning system, a heel plate and the same clamp arm.

Low Roller

The Nova24 and Odin models have reduced Z-axis depth capabilities, so they require the RotoBoss Low Roller model. It’s designed to sit directly on the blades and has a smaller wheel than the other rotary devices. It’s much more affordable than other similar models on the market.

ZnSe AR Coated Lenses

The optical lenses your Thunder Laser comes with should last for years, provided you carefully look after your machine. However, unforeseen circumstances happen, and it’s sensible to have a spare lens kit on hand just in case. These lenses are made from zinc selenide, which is much softer and more pliable than glass. Even the slightest slip when cleaning could cause damage, so you must be extremely careful at all times while handling the lens.

The lens lets the beam focus in on the most minute areas, and focal length, lens diameter and lens shape play a vital role in the finished product.

Laser cutting plywood in workshop for Engraving Machines

We provide a ThunderCAM kit to support you as you create high-precision designs and trace captured images and turn them into 2D designs. In addition to capturing a real-time on-screen view of everything that’s happening on your laser bed, the camera allows you to directly trace shapes or images to convert into vector files to engrave or laser cut.

Lightburn cameras offer an alternative to creating time-consuming jigs so you can quickly and precisely align your work. The control means you can overlay designs with a pre-captured engravable object for optimum accuracy. You can find more information on how to install the ThunderCAM kit on our website.

What’s Inside the ThunderCAM Kit?

We recommend getting our full ThunderCAM kit instead of purchasing a separate camera and accessories to save you time and ensure the adapters are all correct. The kit contains the following items:

- Lightburn camera

- Lightburn camera mount

- USB cable

- USB adapter

- Camera USB cable

- Mounting accessories

Laser Heads

The laser beam passes first through a focus lens in a conical shape and finally through the laser head, which manipulates the laser into your desired shape. You can get a broad range of laser heads with different focal distances. The result is adjustments to the size of the laser dot and differences in how vertically the laser beam points. A longer focus will lead to larger, more vertical dots, while a head with a short focal distance creates a small focal dot with pinpoint accuracy.

High-Resolution Focus Lens

You can get an add-on high resolution laser head that’s specially designed to work with a smaller focal spot than the laser head that came with your Thunder Laser. As a result, you can create more elaborate and detailed engravings, which makes this particular lens perfect for anyone engraving high-definition photos or performing any type of delicate 3D etching.

4-Inch Laser Head

On the other side of the scale from the high-res focus lens is the 4-inch laser head, which is ideal for cutting through thicker objects and not designed for engraving. The head that comes standard with Thunder Laser machines is designed to cut materials with a thickness of less than 10 millimeters, but this size could potentially cause problems if you use thicker materials. It’s possible to create 20-millimeter acrylic items and 18-millimeter wood items with ease using the larger laser head.

Why Choose Thunder Laser USA?

Thunder Laser USA has been on a mission to bring laser cutting machines from large industrial operations to small business owners everywhere. These machines would usually cost thousands of dollars, but we make them accessible for practically anyone with a strong work ethic and a vision to make money. Some of the reasons we’re the best in the business include:

- Our laser cutting machines are designed with simplicity and usability in mind, so there are no unnecessary expensive add-ons — just the functions you need.

- We work with exceptional business partners, including Google, Columbia University, Harvard and many other brands.

- Laser cutting machines from Thunder Laser USA are higher quality than our competitors but cost less.

- We deliver outstanding customer service and have a huge database of user manuals, troubleshooting guides and tutorials to ensure you get the most out of your equipment.

Start Laser Cutting Today

If you’re looking for a new DIY business venture with low overhead and the potential to earn serious income, look no further than laser power! With a CO2 laser cutter, you can get into wood engraving, acrylic cutting, glass etching, woodworking and much more — without any prior know-how or artistic talent. Visit Thunder Laser USA today to get your very own low-cost, high-speed engraving, cutting and etching machine.